Last month I discussed Average Days in Recon (ADR), which laser focuses how reconditioning efficiency and accountability are measured when using reconditioning Time-to-Market workflow software. ADR holds the recon department responsible for only what it can physically touch. It does not include In-transit times or title-release delays.

The clock on ADR starts when the used car manager moves the car from the “In-Transit” or “Trade Not Cleared” categories into a step designated “Recon Starts Now.” It ends when the vehicle is signed off as “Frontline-Sale Ready.” The goal is three days.

NCM Associates reports the average holding cost depreciation in 2017 is $50 per car per day, from the time the dealership acquires a vehicle until sold. The longer it takes a shop to move cars through reconditioning, the more this cost increases. This cost erodes sale gross.

Dealers’ Insights

Many dealers or managers believe they have a handle on their recon department’s ADR. Without using reconditioning workflow software to track this process, however, a shop’s real ADR is a wild guess. Those guesses are often three to five days, but in reality, will average from 10 to 15 days or more.

Last month, I talked to several dealers who are working hard at driving down ADR at their dealerships to learn more about their results.

• Jerry Heinecke is director of used car operations for Morrie’s Automotive Group, which comprises seven dealerships around metro Minneapolis, Minnesota, and Chippewa Valley, Wisconsin. Because holding-cost depreciation erodes gross, getting cars to the sales line faster equals “real savings,” he said. Also, lowering ADR increases inventory turn, and fresh stock sells at substantially greater grosses.

• Trent Waybright is vice president of pre-owned operations for Kelley Automotive Group in Ft. Wayne, Indiana. Based on his reconditioning efficiency analysis of his Chevrolet store using reconditioning workflow software, he said the shop has already shaved three days from its reconditioning process, which adds another $291,951 in sales gross. A three-day ADR grows that to $399,446.

ADR’s Payoff

Here’s how the rubber meets the road:

• Improves Collaboration — Getting to a three-day ADR is a top-down directive. It is a mentality that reduces friction and, instead, helps create new focus, purpose, competitiveness and drive to all departments having an interest in more-profitable used car operations.

• Increases Turn — Better recon practices, tracking and accountability reduces ADR, and that means you can nearly double the new inventory you send to the front line without needing to stock a corresponding number of units to do so.

• Reduces Waste — Group-level reporting tools allow dealers like Morrie’s and Kelley to track recon performance both within and among their stores, using the data to sharpen processes, reduce bottlenecks and manage staff. This is all accomplished in real time, not at month’s end when there’s not much you can do on that dated data.

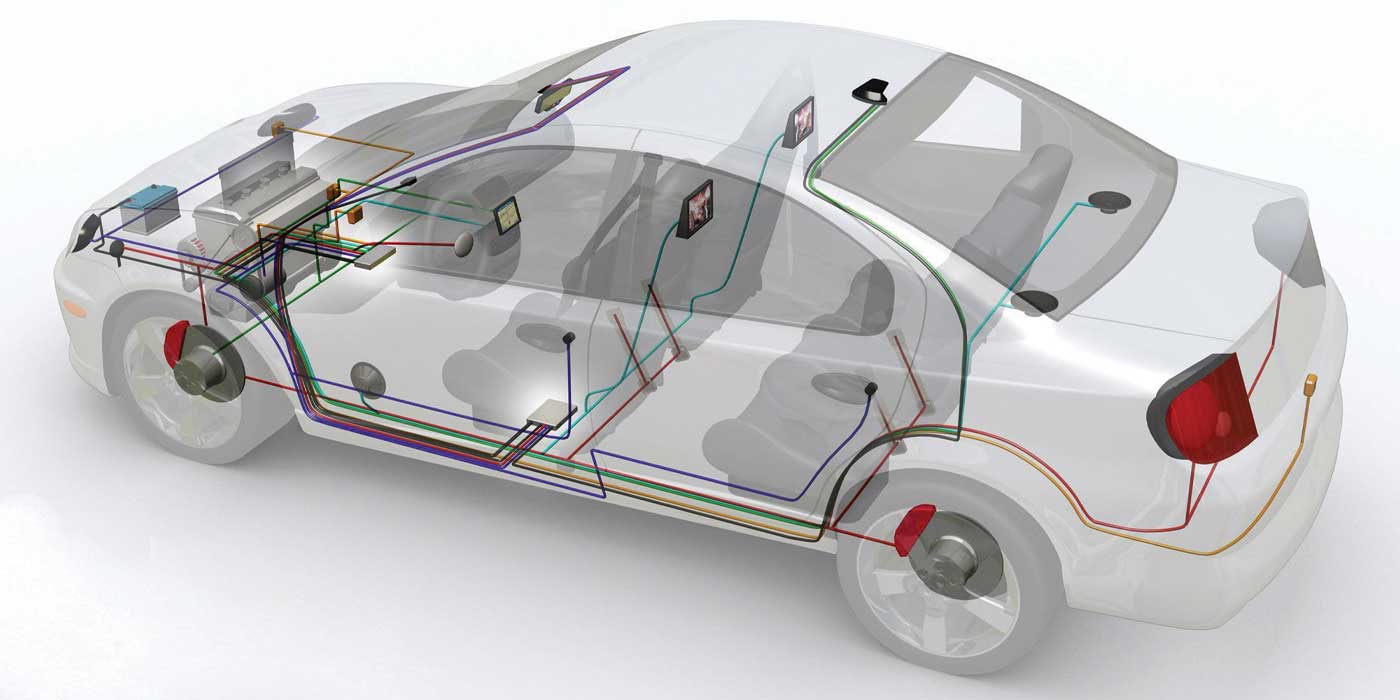

• Harmonizes Work — Recon now runs like a modern factory, with accurate, proven processes supported by profound clarity thanks to tracking and analysis tools. Furthermore, the software brings near-instantaneous communications to team members via text, or phone. Each step in the process is clearly assigned, and the time allotted for that function measured and monitored.

Streamlines, Organizes, Clarifies

Nothing worth doing comes without work, including three-day ADR, but a deliberate effort to transform reconditioning operations brings a substantial return on investment. Accountability and tracking are fundamental to the kind of results needed to prove ROI on such an investment; without measurement, everything is just a guess.

The right reporting tools show daily progress toward ADR — along with bottlenecks, delays and communications breakdowns. Not even the most consistent use of whiteboard or spreadsheet tracking and workflow monitoring can achieve the results dealers get when using reconditioning workflow software and ADR best practices.

Other benefits of ADR include:

• Superior Progress Tracking – You can measure each step in your recon processes, including individuals responsible, per suggested clock-driven productivity metrics. People who know their work is being monitored and measured tend to elevate their output; for those who do not or cannot, you have that data to help with training opportunities or evidence for replacement.

• Uncompromised Inventory Tracking – You know where every vehicle is in the reconditioning continuum, whether in-house or at sublet. You also have a record of where it is parked if taken offline and the individual who last touched that unit. This keeps lost and wayward vehicles from wreaking havoc on ADR.

• Unparalleled Communications – ADR reduces waiting for used car approval on repairs and automatically advances “next steps” notifications up the line to the next individual and department in your recon workflow process. This keeps the entire team connected to your shared playbook, so frustration, errors and miscommunications are reduced — and often eliminated.

“Every car guy tells you he or she can get cars frontline ready in 24 hours with no aging and with good grosses,” Heinecke said. “But to manage all the variables of a modern recon operation, you have to have the right tracking practices, know the data you are basing the decision on is right and only then is it possible to hold people accountable for realizing the results you expect.”