While electric vehicles might still be a rarity in some areas of the country, just about every automaker has an electric vehicle option in its portfolio. This is due to a California mandate that states any automaker who sells cars in the state must have a zero emissions vehicle. This is not a new program — the initial framework was enacted in 1996.

Many of the first vehicles were conventional vehicles such as a Ford Ranger or Toyota RAV4 with an electric drivetrain transplant. But, over the past 20 years the vehicles have become more sophisticated.

Electric vehicles now (and in the future) offer many service and maintenance opportunities. No matter if it is a Tesla or Fiat 500E, when you remove a wheel, you will see brakes, wheel bearings and suspension components that do not look any different than those on a vehicle with an internal combustion engine.

BRAKES

Many electric vehicle manufacturers and owners claim they can get more than 100,000 miles out of a set of brake pads. But these are the lucky few. While it is rare for an electric vehicle to roll up to a shop with the brakes grinding, it is not rare to get an electric vehicle owner complaining about brake noise. There are two factors why electric vehicle have different noise and wear patterns than internal combustion vehicles.

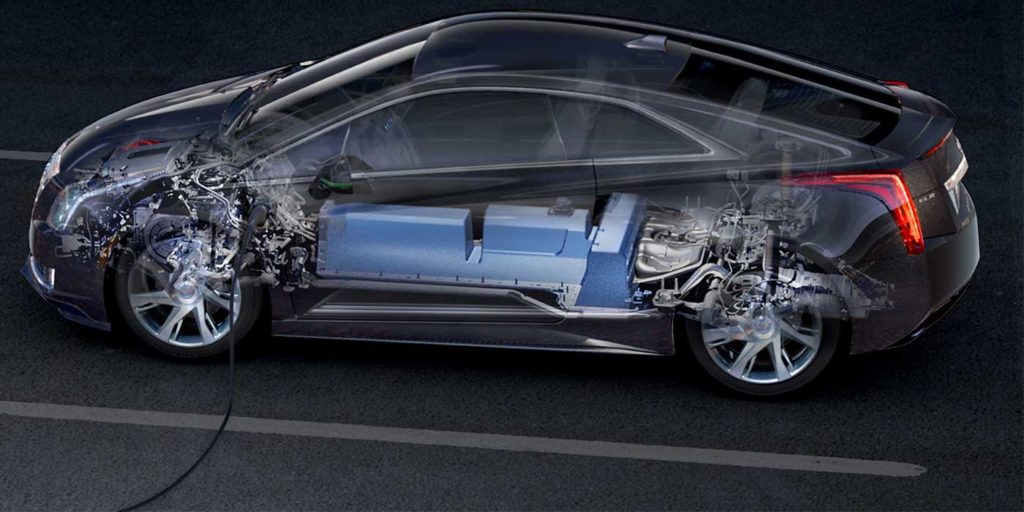

The first factor is regenerative braking. The vehicle recharges its high voltage battery through the use of regenerative braking. With regenerative braking, instead of transforming forward momentum into heat with friction, the drivetrain turns the motor into a generator. The generator turns the kinetic energy into electrical energy to charge the battery.

Regenerative braking can’t be used all the time. At low speeds, when the motor can’t create enough drag to bring the vehicle to a smooth stop, this is when the hydraulic brakes start working. Also, during a panic or hard stop, the hydraulic brakes are used before the regenerative brakes. Wear to the friction material occurs, but at a slower rate. This causes another issue.

The second factor is corrosion. Since the life of the electric vehicle brake pad is longer, the exposure to the environment is extended. Also, lower operating temperatures can exacerbate corrosion.

When replacing the pads, use a high-quality brake procedure and replace the hardware. The anti-rattle clip and pins might look great after a few shots of brake cleaner, but they could actually be worn out and might not last the life of the new brake pads.

Another consideration when selecting brake pads is how the pads are protected against corrosion. Most electric vehicle brake pads do not make it to 100,000 miles, the leading cause is delamination of the friction material from the backing plate due to corrosion. Since the pads will likely be on the car for an extended period, corrosion can destroy the bond. While the environment of the brake pads on these vehicles is to blame, the quality of the backing plate and lack of corrosion protection can make the condition even worse as the paint flakes away.

Look for a brake pad that has advanced corrosion treatments like galvanization. In addition, some aftermarket brake pads use a mechanical attachment to secure the friction material. But, the most important reason to never use a set of cheap brake pads on an electric vehicle is noise. Since an electric motor make a lot less noise and vibration than an internal combustion engine, any brake noise will be noticed by the customer.

The brake rotors used on any electric vehicle are not immune to pulsation and judder problems. Just as with any vehicle on the road, there are specifications for lateral runout, disc thickness variation and minimum thickness. Always measure the rotors for these specifications.

Brake rotors are also prone to corrosion. Since the brake pads are not applied as often, a layer of rust can build up on the rotors. This can cause brake noise and judder. Some electric vehicle manufacturers recommend performing several hard stops to remove the layer of corrosion if this occurs.

SUSPENSION

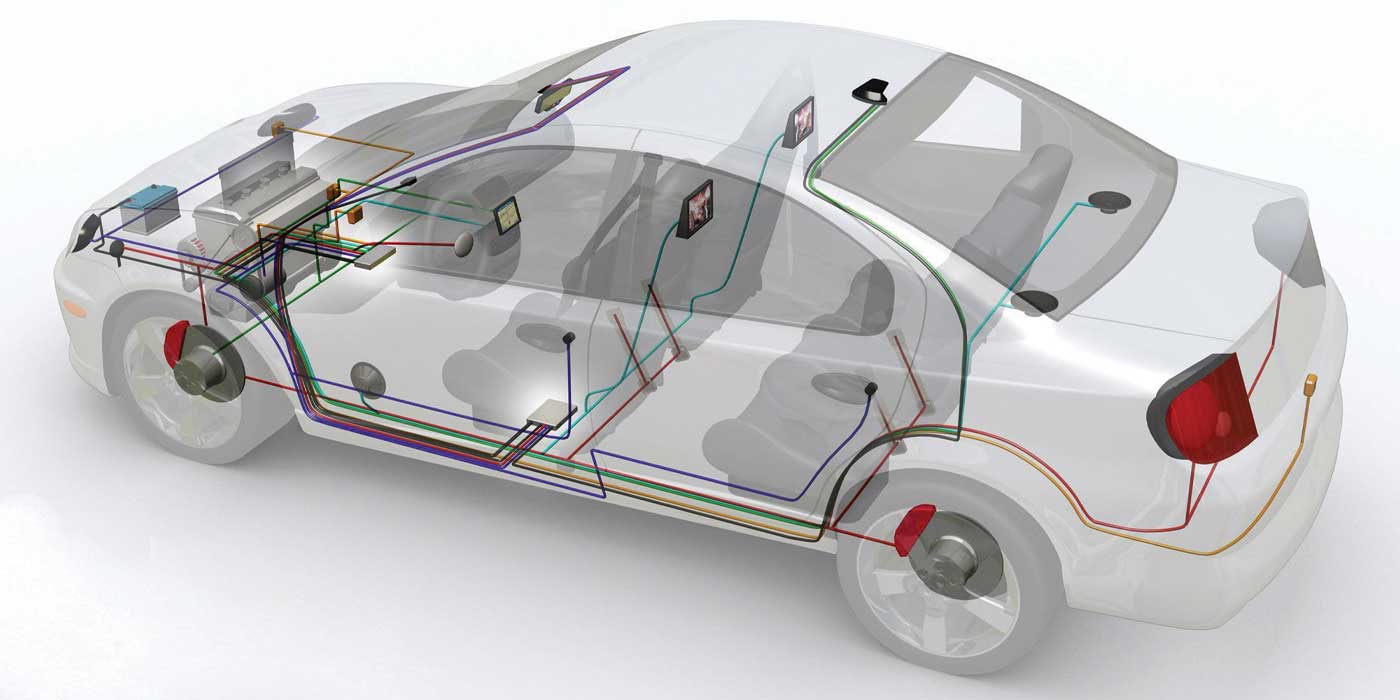

Despite what some people may believe, electric vehicles do not ride on magnets or space age materials. Every electric vehicle still has control arms, ball joints and springs. Like the brakes, due to a quiet drivetrain, worn bushing and strut mounts will be more noticeable.

For electric vehicles to get the most range out of a charge, the alignment must be within specifications. Just a little extra toe out can not only cause tire wear, but also range anxiety. It is highly recommended that the vehicle be aligned annually.

WHEEL BEARINGS

Every electric vehicle has a wheel bearing at every corner of the vehicle. The classic symptom of a bad wheel bearing is typically a cyclic chirping, squealing or growling noise that changes in proportion to vehicle speed.

However, wheel bearing noise in an electric vehicle can also be misleading. The sound may disappear at some speeds or only occur at certain speeds. The noise may get worse when turning, or it may disappear momentarily. If the noise occurs at slow speeds with the brakes applied, chances are the problem is the brakes. If the noise only occurs during acceleration, it could be in the transmission, CV joint or even a worn electric motor mount.