Answering Your Most Asked Questions

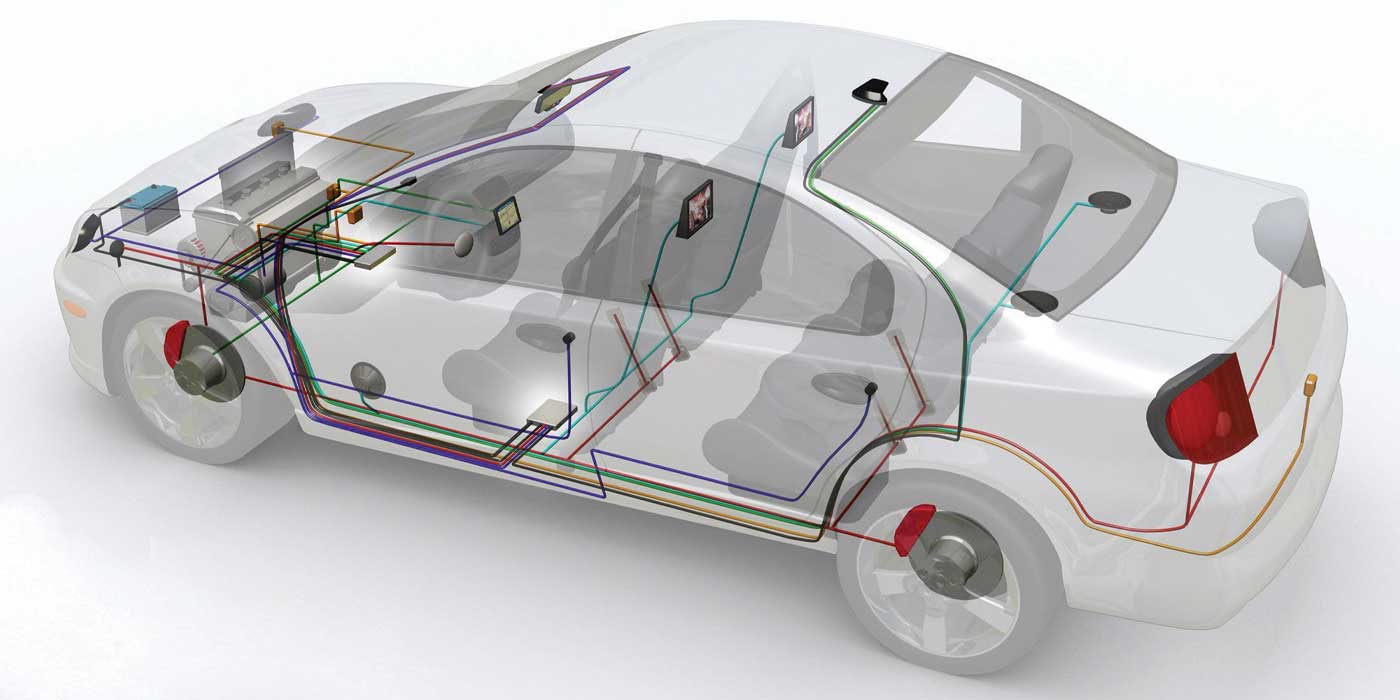

Customer complaints of vehicle vibration and wobbling can usually be solved by balancing tire and wheel assemblies. A proper balance also improves tire wear, increases fuel economy and removes stress on the vehicle. During this crucial process, wheel weights are often the unsung heroes in creating a perfect balance.

When Would I Use a Clip-On vs. Adhesive Wheel Weight?

All wheels can accept an adhesive tape on weight, but not all wheels can accept a traditional clip-on weight. Many times, a customer will be sensitive to the appearance of wheel weights on the outboard plane. For these applications, an adhesive tape weight is the only option. For medium- and heavy-duty trucks, clip-on weights are the best option.

How Should the Material of the Wheel Affect My Wheel Weight Choice?

Both the material that the wheel is made of as well as the style of the wheel will determine what style of weight must be used. For example, most steel wheels will accept a clip-on weight, which is the preferred style of weight for this wheel, especially when the customer is not sensitive to aesthetics. Many modern alloy wheels do not have provisions for clip-on weights on the inboard plane, and even fewer have provisions on the outboard plane. Adhesive weights are increasingly becoming the only option to balance modern alloy wheels.

What trends are you seeing from the OEM level that dictate the use of a certain wheel weight over another? It is clear that most modern wheels are requiring tape weights to include trucks. The market share of tape weights is of course increasing each year.

What Features on Today’s Wheel Balancers Allow for a More Accurate Placement of a Wheel Weight?

The most important feature for accurately placing wheel weights is a “stop and lock” feature. Look for this feature, as well as lasers, when purchasing your next wheel balancer. “Stop and lock” allows the balancer to lock the wheel in place, so that it cannot rotate by accident, causing the technician to misplace a weight. Lasers are critical because they give a visual reference for the technicians to place the weight, making it easy for them to place weight in the right place every time.

What Type of Wheels Create the Most Challenges for Wheel Weight Installation? What Can You Do to Prevent Wheel Weights From Falling Off?

Wheels that create the biggest challenge for installing weights could be wheels that have weight planes very close together, such as motorcycle wheels or very high offset custom wheels. It is recommended that planes be separated by 3 inches.

Proper surface preparation and using a high-quality wheel weight with effective adhesive are key to getting a wheel weight to stay in place. Best practices include using a solvent to clean the wheel where the weight will be placed to remove dirt, grime and brake dust, and then firmly placing the weight.