The first thing that always comes to mind when we’re thinking tire and wheel equipment is a tire machine and wheel balancer. These are naturally the hub of tire and wheel service, but we are going to roll here with a list of tools and equipment that tie them both together to make it as efficient and profitable as it can be for you and your technicians.

Assessing Tire Condition

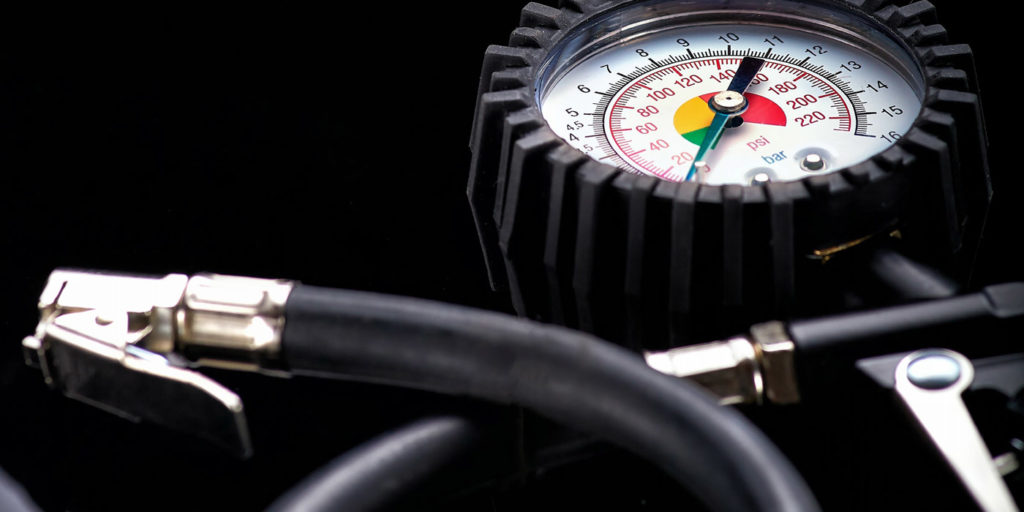

The first step is letting a customer know the condition of their tires. Naturally you’ll want to check the date code and look for signs of abnormal wear that indicate a problem with suspension or alignment, but the two primary tools you’ll use are a tire pressure gauge and a tread depth indicator. Many times, I’m guilty of sticking to old school methods, but digital tire pressure gauges are almost mandatory for today’s cars. The simple fact is they work well, and they are accurate and easy to read. The days of unreliable electronics are gone and, more often than not, it’s your old mechanical gauges that aren’t dependable and difficult to read.

Today’s TPMS displays have the ability to reflect exact pressure readings and your customers will expect that type of accuracy in your work. Digital gauges are the only way to attain this goal and they are available with different types of hoses and feet so you can use the style you like best.

The best thing to happen to the tread depth indicator is the readily available dial-type. No more squinting, guessing and checking two or three times. A dial-type tread depth indicator is quick and easy to use and can even give you increments of one-half 32nd. Believe me, you’ll never reach for that old pocket-clip style again.

Off with the Wheels

Of course, this is the first step that has to be done, and we all know how it works. Pneumatic impacts will always have their place and can be easily argued the most cost effective, but I have to get a plug in here for cordless impacts and battery technology. Most guns will go a whole day if not more on a charged battery and they are just as powerful as their pneumatic counterparts.

What should not be overlooked in this category is your selection of deep well sockets. A socket needs to fit closely on a lug nut or bolt in order to transfer the full force of the blows from your impact. Without the proper fit of a socket, you can pound on a lug nut for hours as the socket bounces back and forth with no effect. This becomes more of an issue with the ever-so-common capped lug nuts that corrode and swell. Get all the sizes you need in both metric and standard, and you also can find metric sockets in half sizes. The more you have, the more trouble you can eliminate. For the lugs that you just cannot grip, keep a lug nut twist socket on hand.

What about the spare? One of our favorite tools for spare tire service is a truck-SUV spare tire carrier tool set. One of these kits will cover all of the various shapes and sizes of these tools that the different manufacturers make, and there will be no more searching behind seats or inside pockets to find it. Quick and easy, just grab one and go to work.

The final thing we’ll talk about in this category is the sledgehammer. We’ve all had wheels so corroded in place you double-check to make sure you didn’t forget a lug nut. A swing from the long handle of a heavy sledgehammer is the solution for the worst examples of this problem, but be sure to keep the head sideways to distribute the force of the blow and if you happen to catch the edge of the rim, it’s less likely you’ll cause any damage.

Cleaning Things Up

Once the wheels are off, now is the time to clean up any corrosion. This is critical. Wheels will not properly seat or torque with a buildup of corrosion. Don’t even think about using an impact to draw them back on. If the wheel does not slide easily onto the hub and fully seat with no effort, you’ve got some cleaning to do.

Hub and rotor surface cleaners are the ticket here, and a die grinder with cleaning discs works great for the back side of the wheels. Be sure to use a non-aggressive disc so you don’t remove any material from alloy wheels.

It’s best to clean everything up immediately after removal so you keep your tire machine cleaner and the wheels will seat properly on the balancer. This is also the time to clean or chase any lug studs or bolt holes, so if you need any new lug nuts, bolts or studs, you can get them coming while you’re changing tires.

Off with the Tires

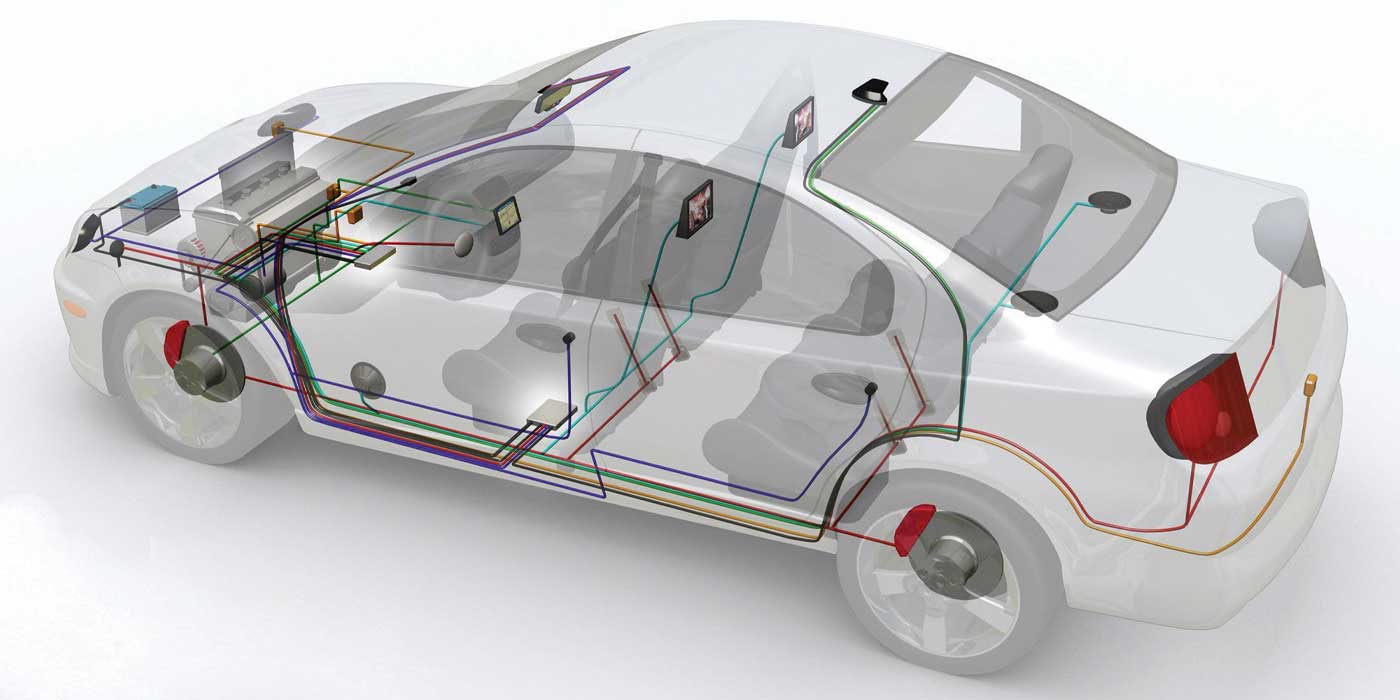

Here’s where your tire machine comes into the game. We all probably know of the vast options available to us now, including the completely touch-free machines, which we all no-doubt agree are pretty awesome, but the common link between them all is compressed air.

As important as the tire machine itself, your compressor needs to be able to handle the demands of your tire machine(s), and still keep up with the demands of all of the other air-operated equipment in your shop.

Some of us may pull the wheel weights off before dismounting the tire and some may do it afterward, but regardless of when you do it, don’t let cheap wheel weight pliers hold you up. Good pliers work perfectly every time. Cheap ones will make you fight each and every weight, and you’ll probably pinch your fingers in the process. Spend the money, get the good ones, you’ll never regret it.

Adhesive weights have their own special tools for removal too. Plastic knife-edged tools are made specifically for this job and won’t gouge or scar aluminum wheels, not to mention they offer excellent leverage. Put that pocket screwdriver or putty knife away!

Prevent Those Leaks

There’ nothing more frustrating to customers and technicians than a comeback, especially for a new tire that loses air. Cleaning the sealing bead of the rim is critical, and I’ve seen a number of different methods from sandpaper to angle grinders with wire brushes. Whatever you use, make sure to get it done.

Often overlooked is the valve stem. The snap-in (rubber) style is the easiest to replace and is utilized for both pre-TPMS vehicles and some TPMS vehicles as well, depending on the type of sensor. The clamp-in style of valve stems associated with some TPMS sensors utilizes separate seals and takes a little more time to do it right, but as with all of this, there are tools to make it easier. For both, keep a set of small round wire brushes to clean the hole for the valve stem. A lot of technicians simply don’t look closely at this hole and more often than not there is corrosion there. It’s one of the more common causes of leaks. Take the valve stem out, clean the hole and put a new one back in.

Clamp-in sensors need to be torqued, and you can get torque screwdrivers that are set specifically for this to make it quick and easy. Replacing rubber valve stems has always been a standard practice, but the better equipped you are for the TPMS clamp-in stems, the easier it will be. You’ll make extra money on the stems and prevent comebacks at the same time.

Plugging the Tire

Most mainstream tire shops plug from the inside using rubber preparation chemicals and cement on the plug. The tools for this can vary depending on whose plugs or patches you use, and if you’re using plugs that are installed with the tire still mounted, there are some very nice kits available with self-vulcanizing plugs and sturdy-high leverage tools. Maybe you have both. Either way, the right tools get the job done quicker.

Before It Goes Back On

If you’re replacing TPMS sensors, there are a couple things that come to mind. One, a good source to look up sensors, and the internet is your primary tool. Websites such as dill.com allow you to look up the exact sensor for any car and also provide you with information to reprogram the TPMS sensors. Your TPMS scan tool is vital here as well, and if you have any question about whether it will communicate with a certain brand of sensor, make sure you test it before installing.

The Balancing Act

Wheel balancers also fall into that category where we all know how nice they can be, but regardless of what you have, the most important part is keeping all of the adapters necessary to properly mount and hold wheels in place. A lot of new wheels, especially those with faux-alloy covers, have the tendency to slip and throw off the balance. The problem is that you can’t tighten them down enough with traditional balancer adapters or you may crack or scratch the plastic cover. You may have to get some additional adapters or get creative with the ones you have to make sure the wheels stay put when you spin it.

Aside from that, your balancer will do its job and we’ll go back again and mention the high-quality wheel weight pliers that make it easy to hammer them on.

Back on the Car

Once the wheels are back on and the lug nuts or bolts are started by hand, a torque-limiting socket (torque stick as they’re commonly known) is a good, quick way to seat the lug nuts. Make sure you use one that is always below the torque specification of the wheel. Too much torque, even by just a little, can distort the lug nut seats on the wheel, damage the threads of the lug nut or bolt, or damage brake rotors or drums. It’s best to be below torque and finish it up with a torque wrench.