In a world full of vehicles that have ADAS features and the trust that more drivers are putting in these safety advancements, proper operation of all components is more important than ever.

The novelty phase of autonomous driving and driver-assist features in today’s new vehicles has worn off. The ADAS features have become a viable force in the way people trust their vehicles to assist them when they need it most. A good example would be your own habits. How many of you are turning your head to look in your blind spot? How many of you just look in the mirror and check to see if the light is on? It’s funny how easily people will accept and adapt to something that makes everyday life a little easier.

The ramifications become apparent when that trust becomes dependent on the features. If by some circumstance they fail to perform, who will be to blame? The driver? The OEM? The shop? The insurance company? Interesting thoughts. I’m willing to bet somewhere, somehow, we’ll be learning the answer to that question soon. I’ve always said: 12 people who could not get out of jury duty will decide the direction of an industry.

The only protection we as an industry have in this type of predicament is to do the repair correctly and validate that we did so. It is also the responsibility we have to the consumer, who has entrusted us as an industry with the safety of their family. It seems simple, but there is resistance by some in our industry to all the procedures recommended or required to be done to repair a vehicle correctly and validate it was done correctly — not just in the world of electronics, but all aspects of repairing today’s vehicles. One of those procedures is vehicle alignments. How does an alignment affect new electronics such as ADAS features? Where does a shop need to be concerned? What’s an alignment got to do with ADAS?

The Basics

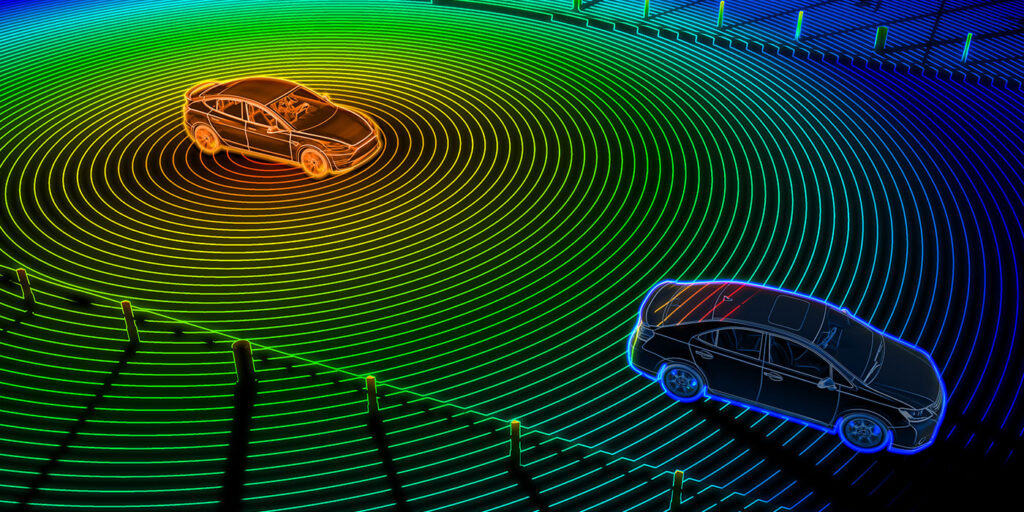

First, let’s break down some basics. ADAS has many features to assist drivers or actually take control of the vehicle when a parameter is met. Depending on the level of advancements in a particular vehicle, these responses rely on the fact that the vehicle is correctly communicating and aligned with all sensors to indicate where the vehicle is in relationship to the roadway. This is accomplished through cameras and radars and the forces and environment the vehicle is experiencing through G-force sensors and ABS. All of these inputs produce the desired output from the vehicle for the event the vehicle is sensing. The vehicle does not know you’re in danger, it just reacts to inputs it’s being given. So, the phrase in computers and electronics of “garbage in equals garbage out” comes into play. If the vehicle is not correctly calibrated to all inputs, the output may not be the desired result.

That’s the human driving portion of ADAS features. The electromechanical power driving features and parking features adds even more complexity to the process of repairing and validating that the repairs are done and calibrated correctly. With all the sensors and controllers compensating for roadway changes, it doesn’t take much deviance from OE specs to produce an incorrect input that will affect one of these features. The simple complaint of “My car seems to be pulling to the left” now becomes a much larger diagnostic process to find out the root cause. There is no light or DTC to guide you on something not being aligned correctly.

We know all the sensors need to be correctly aimed on the vehicle’s structure to “see” down the road and in the correct zone of view to function correctly. Even a slight deviation will have an influence on the operation of the ADAS features.

Another factor is the vehicle needs to be aligned to steer correctly in certain modes of operation such as lane keep assist, lane departure, parking assist and backup cameras. The validation that the steering wheel angle sensor is correct to vehicle alignment is a major component to the safe operation of these systems, as well as normal driving. This leads the focus to four-wheel alignments being required to validate that all components are aligned correctly.

Alignments

An example would be a vehicle with lane keep assist. An alignment issue has created a slight pull to the left. This is steering the vehicle to the centerline of the lane of traffic the vehicle is in. The vehicle lane keep assist is correcting constantly to bring the vehicle back to center. Not only is the driver being annoyed by having to keep correcting or putting pressure on the wheel to stay in the center, but due to the frequency of the corrections, the vehicle is indicating to the driver to stop and take a break as the vehicle is sensing that the driver is wandering in the lane.

There is also a danger to this constant pulling to center. If you’ve ever operated a vehicle in this mode, you may have experienced the moment you as a driver begin to correct your position in the lane and the vehicle corrects itself too at the same time. This overcorrection can be a little startling for a driver. Now, picture this happening on an icy road or snow conditions for a driver who isn’t prepared for it.

Another example is using the backup camera that all vehicles now come equipped with. The camera and computer that uses the wheels’ angle to track the vehicle’s direction are dependent on the vehicle’s alignment. A steering wheel or backup camera that is out of alignment may cause improper performance of the vehicle. It is no longer just about adjusting camber, caster and toe; it is the ripple effect an incorrect working component will have on the vehicle’s features or safety systems. We as repair professionals must look at the entire picture versus having a narrow focus on a component.

Calibration

Many vehicle manufacturers require that a calibration be done after a wheel alignment is performed. As mentioned before, it’s critical to validate that all the vehicle sensors are in sync to the vehicle manufacturer specifications as to how the vehicle is aimed and steering down the road as well as the attitude to the roadway (height and pitch or yaw angles). This is evidenced by some OEMs having prerequisites before a calibration is performed, such as a full tank of gas and a level surface. This seems like a nuisance to a shop, but it is a required step to validate to OE specs. I’ve seen demonstrations showing the difference in how the vehicle is aligned to the road when a vehicle has a full tank of fuel versus half a tank — and they prove that following the OEM’s prerequisites is critical.

For collisions that require a wheel alignment due to the damage, the alignment should be done prior to any calibration. What happens if the damage from the crash does not warrant a wheel alignment? This has perplexed the auto repair industry. Do we need to verify that the alignment is correct before doing a calibration? Regardless of the damage, some OEMs go as far as to say that an alignment must be done prior to a calibration and even the calibrations need to be done on an alignment rack.

An example would be the fairly straightforward procedure of replacing a grille on a vehicle. There is no damage to the suspension, but a calibration will be required. Is a wheel alignment called for? This depends on the OEM statements for their vehicles. I see both sides of this argument as to the necessity and price of repairing vehicles. I also see the argument of validating that the vehicle is operating correctly. Is the alignment a result of the incident or is this unrelated prior damage negating alignment costs to the third party? This is a complex question that is beyond my ability to give you advice as far as the legalities. You as a shop owner have to develop your own response.

In doing some research on the mechanical repair industry, I found that when a calibration is called for after an alignment or even tire replacement, it is predominantly customer-pay. Could customer-pay be a bigger part in the collision industry for collision claims? Customer-pays for unrelated services needed to complete repairs correctly? This may be a necessary conversation to have with vehicle owners before beginning repairs as more advanced features come into play.

Summary

The vehicle’s alignment directly interacts with all of the vehicle’s advanced features. When to do an alignment is more the question; we know when damage from the crash requires it.

When we do not verify alignment before a calibration, we may have a successful calibration. So, when the customer comes back with drivability issues, who is now responsible? That is something to think about. Proper alignment has everything to do with ADAS features.