By: Fardad Niknam, courtesy of Tire Review magazine

Have you ever wondered about the science behind a tread pattern? Why some tires have a lot of cuts, some are almost slick, some are asymmetric, and some are directional?

The only contact a car has with the road is the tire so tread patterns play a critical role on how well the tire performs in different road conditions. Engineers spend hundreds of hours developing a pattern that will provide optimum performance in the realm of target conflict, where expectations are really high. They have to consider the interaction between the tread pattern and compound to assure the interaction will not compromise the other performances.

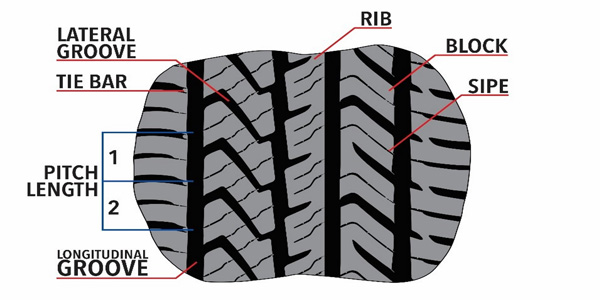

Before we get into the details, let’s spend some time making sure we use the same terminology on the tread pattern components.

Figure 1 shows the main components of a tread pattern. Most of the definitions are standard in the tire industry, but some may vary from company to company.

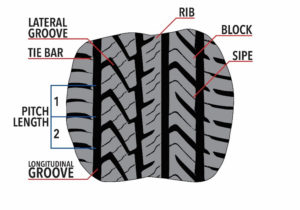

Tread Pattern Performance Expectations

While tread patterns have a major role in the performance of each and every tire, engineers mainly focus on dry braking, noise, wet braking, handling, PRAT (Ply Steer Residual Aligning Torque), irregular wear, and snow and ice traction in regards to the design of a tread pattern. Besides tire performance attributes, creating an attractive look is an important aspect of a tread pattern design, too.

Figure 2 illustrates the main performances of tires influenced by tread pattern.

The challenge when designing a tire is managing the trade-offs, where improvement of one performance attribute will result in a performance reduction in another area. The best dry braking tire is a slick tire with no groove or sipes, which is why racers use “slicks” in competition. A slick tire provides a maximum contact patch with the road and delivers ultimate performance in dry conditions. However, the same exact tire will not be driveable on a snowy road.

Winter tires with a lot of sipes will provide excellent snow performance, but are not ideal on dry roads. On a snowy road, sipes will act like claws, digging into snow to move the vehicle through it. That’s why winter tires are highly siped.

Figure 3 shows the difference between a summer tire and a winter tread pattern.

The same is true regarding the target conflict between wet braking and dry braking. The tread pattern should be designed to evacuate water quickly from the tire in wet conditions through circumferential and lateral grooves (tire void). A tire with a high void concept (large grooves in circumferential and lateral) will provide excellent wet braking performance, however, a high void pattern reduces the contact patch, resulting in lower dry braking. Developing an optimum tread pattern to deliver both performances is always challenging for tire engineers.

Noise and irregular wear are the other two main tire attributes that should be considered during tread pattern development. The number of pitches, sequencing the tread pattern pitches and the position of different grooves will affect noise performance. While a higher pitch may improve noise performance, it may also reduce block size and increase the risk of irregular wear on the tire. Smaller blocks will reduce dry performance of the tire as well.

The tread pattern also provides some important performance attributes that may not be known to the public. For instance, every road is built with some slope toward both shoulders. These slopes help with the evacuation of water from the road. The goal of a tire engineer is to design the pattern in a way to generate enough force to keep the car going straight when there is no steering input or correction available. Block angles play the main role and have to be designed to make this work.

As we discussed earlier, tread patterns also play an important part in tire handling. Tire engineers normally design tires asymmetric where there is a different expectation of handling from each side of tire needed. This is normally true in UHP tires where the expectation of handling and performance is very high. When the appearance is the main factor, the directional pattern can be considered.

Figure 4 shows the difference between asymmetrical, symmetrical, and directional tread patterns.

Tread pattern is not the only tire performance influencer. Tread compound, tire contour and tire construction combine to provide the total performance of the tire, and the interaction between them all is an interesting subject for future articles.

In modern days with the availability of super computers, tire engineers are able to develop tread patterns, model the tire and predict the performance, identifying which will provide the best overall performance and safety before ordering any tooling. It’s a process that helps us to bring tires to the market in half of the time it took a decade ago. Of course, the true tire tests happen in our proving grounds, where each pattern’s performance is individually confirmed before going on the vehicles of the customers you serve.