Here’s a question often asked when dealership group managers gather, which unfortunately typically goes unanswered: “How many of you know your average days in recon?”

The question goes unanswered because almost anyone not using a reconditioning workflow tool is managing recon by “guesstimate.” The average days in recon (ADR) measurement is every bit as much a key performance indicator of your productivity, efficiency and profitability as are sales volume, days’ supply and contracts in transit.

ADR measures time, in hours. The ADR clock typically starts at mechanical inspection and stops after recon moves the car to the sales lot.

ADR measures what recon has actual control over — what they can actually touch. The time to line (T2L) clock, another key metric, starts at auction, trade or private-party acquisition and ticks until the car is moved to the sales line. So, there is overlap, but note: T2L includes time not under recon’s direct control.

T2L includes time a purchased vehicle sits at the auction before getting on a transport, travel time to your recon facility, delays in release from finance and time vehicles might wait to move into recon — and often, time cars sit forgotten or neglected at sublets.

Profitable reconditioning works to reduce or eliminate T2L delays and make ADR more efficient. Rapid reconditioning tools enable precise tracking control over these phases as it identifies bottlenecks and delays so they can be removed.

The difference between not knowing ADR and T2L and knowing these measurements and reducing them is the difference of tens to hundreds of thousands of dollars a year in eliminated vehicle depreciation and lost sales margin.

Furthermore, unless you are practicing rapid reconditioning, any inventory management system you employ cannot deliver the results you need. A long recon cycle leaks margin and builds up overhead costs that even the best inventory management system will not be able to recoup.

From my research, dealers practicing rapid reconditioning note:

• “Inventory management tools aren’t as helpful as they can be if cars are hung up in the recon process,” said Rod Rowley, senior vice president for the Larry H. Miller Group of Companies. “These tools are more effective if you also have efficient reconditioning pushing inventory into these systems faster.”

• “We pay particular attention to days’ supply of our inventory, and practice a velocity-based model, a time- and age-sensitive inventory method,” said Ted Chapman, CEO of the Chapman Automotive Group. “If I can reduce inventory aging as a result of a more focused and coordinated reconditioning process, I’m buying time. As a group that once took an average 11 days to get vehicles from acquisition to the sales line, cutting that time in half gives us another week of action with that asset.”

A T2L culture:

• Defines work to be done to achieve a specific outcome and brings clarity to processes and procedures — who does what, when and in what timeframe

• Identifies critical steps in each process and alerts management about activities that might be streamlined further or even eliminated, so workflow speed increases and costs removed

• Assigns people having the right skill sets to the correct task assignments to ensure workflow efficiency and quality

• Builds rhythm-and-flow into the work — and confidence in those individuals challenged with delivering faster T2L

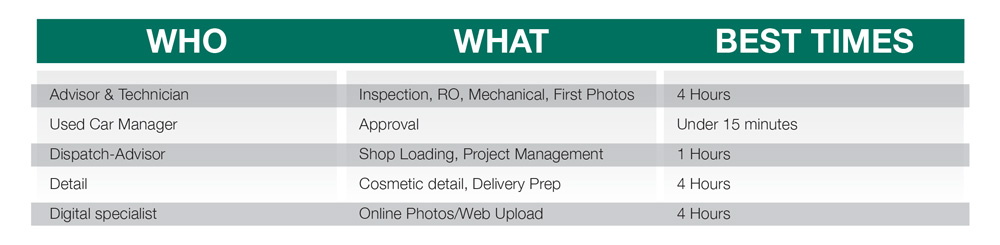

As recon itself has control over vehicle movement once recon personnel can actually lay hands on their cars, ADR efficiency begins here. The table below, which appeared here in AutoSuccess magazine last year, is so illustrative that we’re using it again now. It identifies critical steps to ADR and best-practice times for each step. How do you compare?

Stop attempting to measure and track such a multi-faceted, multi-step, multi-process activity as vehicle reconditioning using a spreadsheet on a desktop computer or whiteboard on a wall. Those techniques will never help you identify your real ADR. When group managers are asked, “How many of you know your average days in recon?” their actual ADR will be on average eight to 12 days or more than what they believe it to be if they lack rapid reconditioning tools to measure their processes.

By using workflow tools to manage ADR, a three-day goal is achievable. Perhaps that ADR isn’t realistic for your shop, but a seven-day ADR might be. The point is to use these practices to reduce both ADR and T2L.

Reducing T2L and ADR has the following benefits:

• It moves vehicles into hands-on reconditioning fast — often saving a day or more off T2L.

• It increases inventory turn, which means more cars sold during a month. Every 2.5 days’ reduction in ADR will drive one more turn per year.

• It maintains gross by ensuring more vehicles reach the sale lot having most of their magical 21 days of prime retail sales window available. A car in recon for 10 days leaves only 11 days to sell at maximum gross — afterwards, profitability plummets.

• It reduces holding cost depreciation, a cost every used car incurs from date of purchase to the time of sale, eroding sale gross. NCM Associates estimates this percentage of overhead cost at $40 per vehicle per day, from acquisition to sale.

• It leverages mobile technology to simplify and speed work approvals and other communications among managers and staff.

• It delivers better control of inventory location identification and status throughout the workflow; no more “lost” inventory on back lots or sublets that mean lost sales and lost profits.

Dennis McGinn